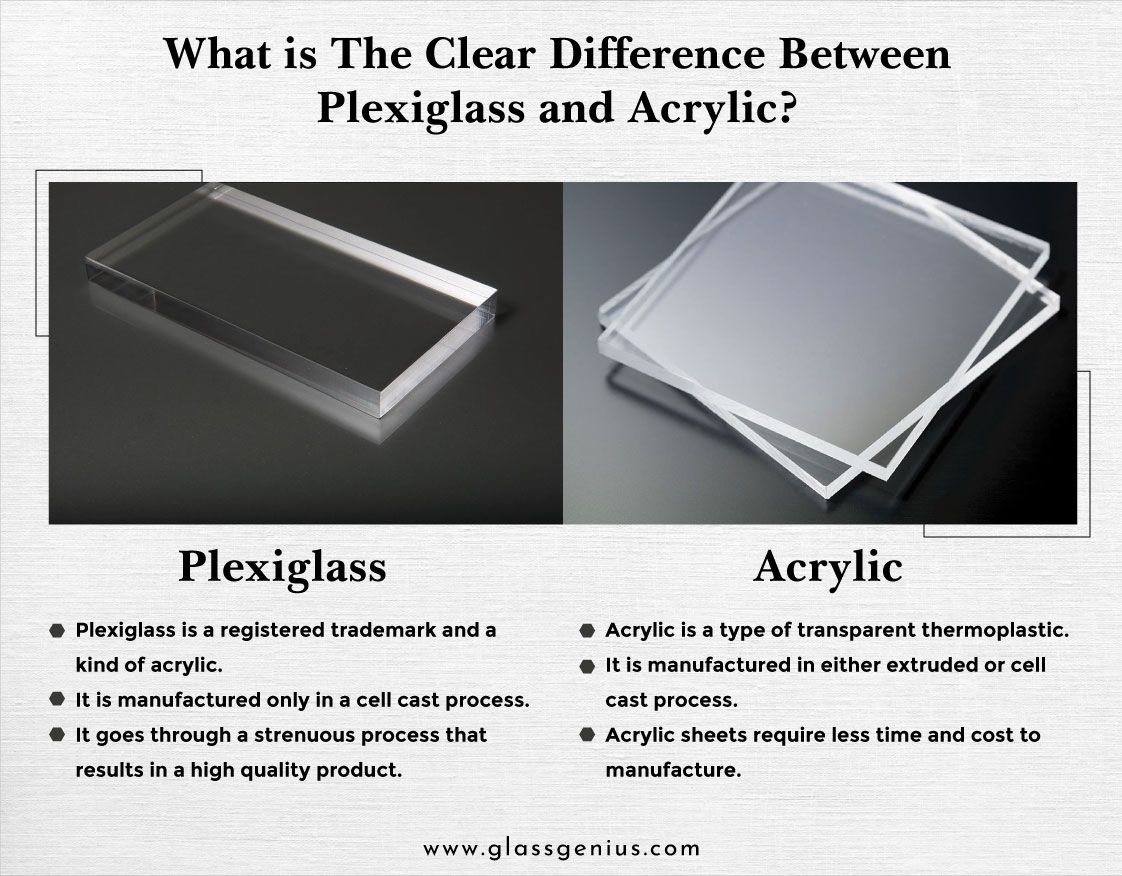

Many times we see people get confused between plexiglass and acrylic glass. In public dealings and online blogs, commonly we hear that there is absolutely no difference between acrylic and plexiglass. Whether both are two different names for the same product? If so, why is it named in two different terms? Though both the terms are very much similar, there is a notable difference between the two.

In this blog, you will learn the key difference between plexiglass and acrylic, and some recommendations & uses. Before going ahead, let’s explore these two terms separately. Plexiglass vs Acrylic:

The Plexiglass

Plexiglass has a generic trademark used for acrylic sheets. Just like the Super Glue has a trademark used for Cyanoacrylate. After the invention of acrylic in 1928, one of the manufactured forms was registered with the name Plexiglas. At present, various companies manufacture plexiglass under different brand names like Crylux, Perspex, Acrylite, etc.

The Acrylic

Acrylic has technically called polymethyl methacrylate. It is a transparent thermoplastic that is a strong and durable alternative to glass. For this reason, it has various applications such as windows, planes, aquariums, LCD screens, and modern furniture. Though glass is less costly and elegant, acrylic sheets are highly durable and shatter-resistant. Moreover, they are impact-resistant, which makes them favorable for areas that are prone to storms or even hurricanes.

Being an excellent alternative to glass, acrylic has plenty of applications in construction projects, interior decor, eyeglass lenses, sneeze guards, wall separators, and solar panels. Due to its less glare and ease of cutting, acrylic sheets have frequently been used in DIY projects.

Is Acrylic The Same As Plexiglass?

As a material, appearance, and application, both acrylic & plexiglass are the same things. Both carry the same quality and features. However, we can discriminate between both terms only technically.

So, are you curious to find out the clear difference between plexiglass vs acrylic? Read further to know how both technically differ from each other.

Plexiglass vs Acrylic: A Clear Difference

Basically, the difference doesn’t lie in the material but in the manufacturing process. Acrylic sheet manufacturing involves either of two techniques: extrusion or cell casting. With the former technique, the process is continuously carried out to make acrylic sheets. In contrast, the cell casting technique involves a strenuous amount of effort, time, resources, and cost. For this reason, the latter process is a bit more expensive but gives more quality and durability.

Plexiglass has made only through the cell casting technique. For this reason, if you are paying more here, it is not just for the value of the trademark. It is for the value of a more comprehensive manufacturing technique to make it a quality product.

Related: A Comparison of Acrylic (Plexiglass) vs Polycarbonate (Lexan) Glass

Final Thoughts

Discriminating plexiglass from acrylic is much more difficult without looking at its manufacturing technique. Plexiglas has a famous registered trademark used for acrylic. That is why plexiglass has been used frequently in marketing to show that acrylic is of high quality.

Finally, you have understood the clear difference between plexiglass and acrylic, it will ease your buying decision regarding acrylic sheets. If you need to buy quality acrylic ( i.e. plexiglass), visit the Glass Genius marketplace to place a customized order.

FAQs

Technically, plexiglass manufacturing involves the cell cast process, which is more strenuous than the extrusion process used for acrylic sheets. For this reason, acrylic is cheaper than plexiglass.

The extensive manufacturing process used in plexiglass makes it more durable than acrylic because it involves the reaction of acrylic within glass panes that makes a cell. After the reaction, the glass is separated and the acrylic is passed through the inspection for quality.

It depends on the area where it is going to be used. Acrylic may possibly be yellowish over time if the sun bombards heat continuously over that area. Otherwise, continuous maintenance and care make it a highly durable product.

DIY cutting plexiglass is very easy and requires minimal skill. Simply, you need the equipment that you usually have, and you are good to go. Just read our guide on “How to cut plexiglass?”.